Quick and easy digitalisation

Shoestring’s simple, inexpensive approach helps companies satisfy real business needs.

Why Shoestring?

- Work out what you need

- Find suitable options that fit in your business

- Justify the benefits and return on investment

Why Shoestring?

- Work out what you need,

- Find suitable options that fit in your business

- Justify the benefits and return on investment

What is Shoestring?

Shoestring is building a global community focussed on practical digitalisation for small and medium sized businesses.

At Shoestring, we believe that the best way to learn is by doing, so we use low-cost, off-the-shelf technologies to build digital solutions that solve common problems.

We offer starter solutions which are small-scale solutions that provide immediate benefits without disrupting core operations, help build digital confidence and skills, and prepare employees to embrace further digital technologies.

What is Shoestring?

Shoestring is building a global community focussed on practical digitalisation for small and medium sized businesses.

At Shoestring, we believe that the best way to learn is by doing, so we use low-cost, off-the-shelf technologies to build digital solutions that solve common problems.

We offer starter solutions which are small-scale solutions that provide immediate benefits without disrupting core operations, help build digital confidence and skills, and prepare employees to embrace further digital technologies.

Simple solutions to meet real business needs

Job

location tracking

Power

monitoring

Scrap

monitoring

Downtime

monitoring

Air quality

monitoring

Temperature

monitoring

Be part of Shoestring

Many different people use Shoestring to improve productivity, meet sustainability goals, build digital and technology skills. They range directors to managers and operators, from production and business development teams, and include apprentices, tutors and researchers. Discover how you and your organisation would benefit from joining us:

Businesses

Education institutes

Regional organisations

Programmes and activities

Regional programmes

Develop a funded regional or sectoral programme to enable businesses to get started with digitalisation.

Hackathons

Bring together members, employees, apprentices to solve industry challenges using low cost technologies.

Workshops

Host a workshop to help your members identify which digital solutions address their top needs.

Self-start programmes

Manufacturers can join 6-8 week training programmes to help them deploy their own low-cost digital solutions.

Applicable across multiple sectors

Many companies face similar business challenges, from expensive energy bills or time wasted trying to locate jobs on the shop floor to high scrap waste and machinery downtime.

We talked to over 450 small and medium sized companies across a wide variety of sectors, and found that many of their needs were very similar, just described differently. The digital solutions required were often the same whether they worked in construction, logistics, manufacturing, or healthcare.

News

Shoestring and Made Smarter AI Integration and You

15/01/2026 Made Smarter & Shoestring. AI Integration and You Join Made Smarter, Cambridge Kinetics & Shoestring as they demystify AI and how it can help your business This Made Smarter session—run by Cambridge Kinetics - is a practical, no-jargon workshop for...

LoDiSA 2025 Showcases Global Momentum for Low-Cost Digitalisation

28/10/2025 LoDiSA 2025 The third edition of the International Workshop on Low-Cost Digital Solutions for Industrial Automation (LoDiSA 2025) took place at the University of Cambridge on 23–24 September, bringing together researchers, industry leaders, and innovators...

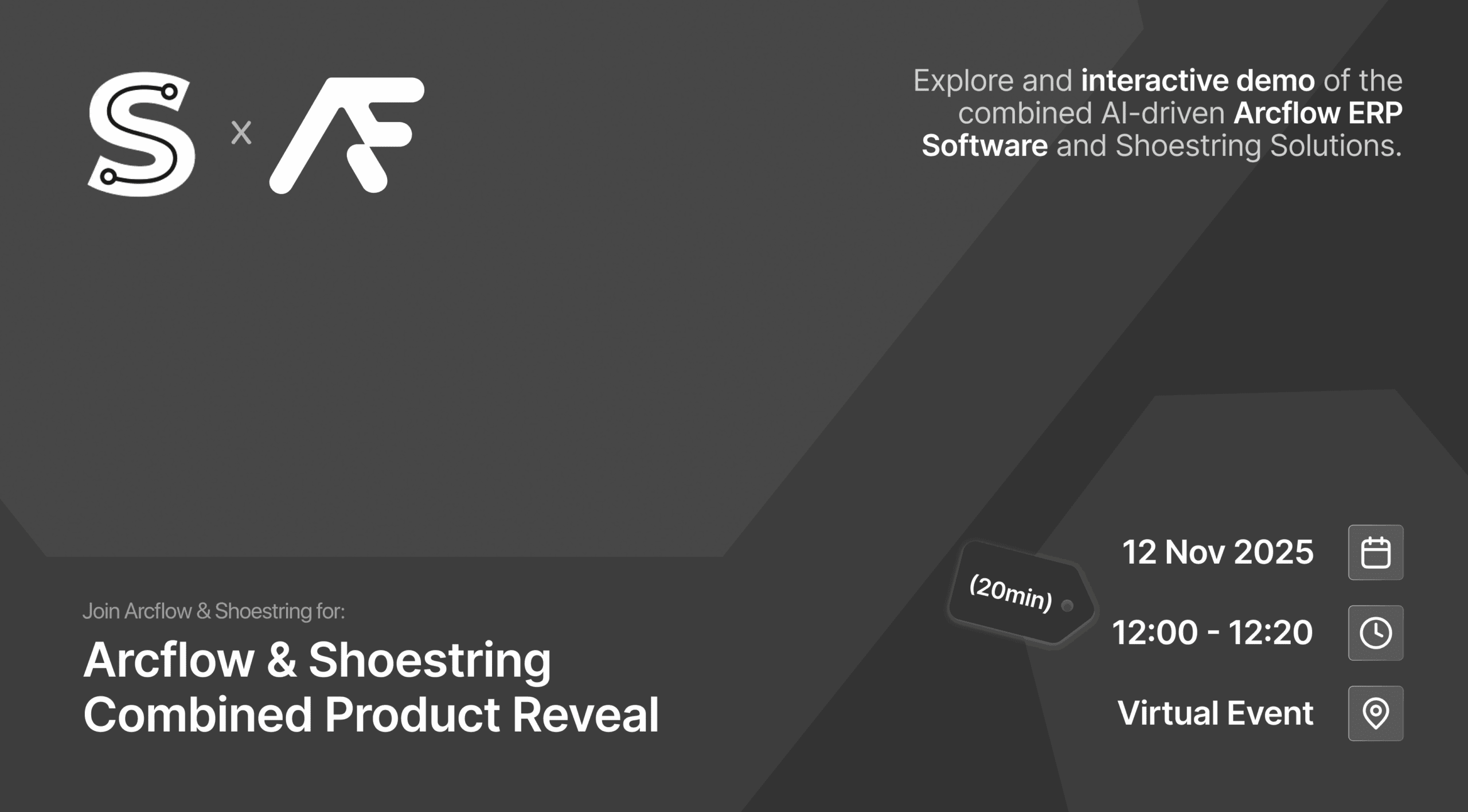

Shoestring and Arcflow interactive demo

16/10/2025 Arcflow & Shoestring Product Reveal: Interactive Demo for UK Based SME Manufacturers & Distributors. Are you an SME manufacturer or distributor in the UK looking to digitise operations without the high costs of enterprise systems? Join us for a free...

Events

Case studies

Shoestring introduces starter solutions

Shoestring takes its first steps into commercialisation to help companies tackle digital transformation.