How can we help your business?

The Digital Manufacturing on a Shoestring programme is developing an affordable, non-invasive, easy to implement approach for companies who want to start trying out digital solutions right away.

The project integrates low cost, off-the-shelf technologies such as QR scanners, WiFi cameras, sensors and micro-computers, along with openly available software, into digital solutions for industry – all from as little as £200.

With input from more than 450 companies in the UK and overseas, Shoestring has built up an accurate picture of the common digital challenges facing small-to-medium sized companies today; many of which can be matched and addressed with a low-cost solution.

Top 10 digital requirements

As identified by manufacturers

- Job tracking (location & status)

- Unified change management and issue reporting between design and production operations

- Digitised work instructions and assembly procedures

- Capacity monitoring (human and machine resources)

- Process monitoring

- Gathering and analysis of product or customer demand

- Machine or process configuration support

- Predictive maintenance

- Internal lead time monitoring

- Job scheduling (human and machine resources)

Find out how Shoestring helps manufacturers

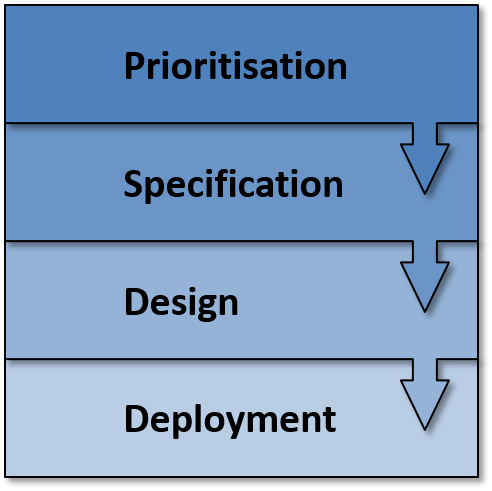

Walk through the Shoestring approach step-by-step.

See how companies have transformed their operations using Shoestring.

A mix of manufacturers, solution providers, technology suppliers, regional associations and education institutes who are helping build the Shoestring community and add value to the UK manufacturing sector.

Find out how these workshops help organisations, networks and companies realise how their group’s specific challenges can be addressed.