Power monitoring (up to 50A)

Power monitoring helps companies understand energy consumption by tracking actual equipment power usage.

Shoestring’s power monitoring starter solution package** gives companies an easy way to get started, see how digitalisation benefits their business, building in-house digital skills along the way. The starter solution is designed to provide a practical learning experience.

Each starter solution package:

- Can be built and deployed by non-technical staff

- Is supported with a technical training and support programme, instructions, an online forum for problem solving

- Facilitates peer-to-peer support as well as access to experts

- Provides a detailed shopping list of the low-cost electronic components (all available online from major resellers)

- Includes the software required to connect the components and deliver easy-to-understand dashboards.

** We are currently offering a special early adopter offer on a first come first served basis – £400 for a starter solution package (saving £400 on full price).

How the solution works

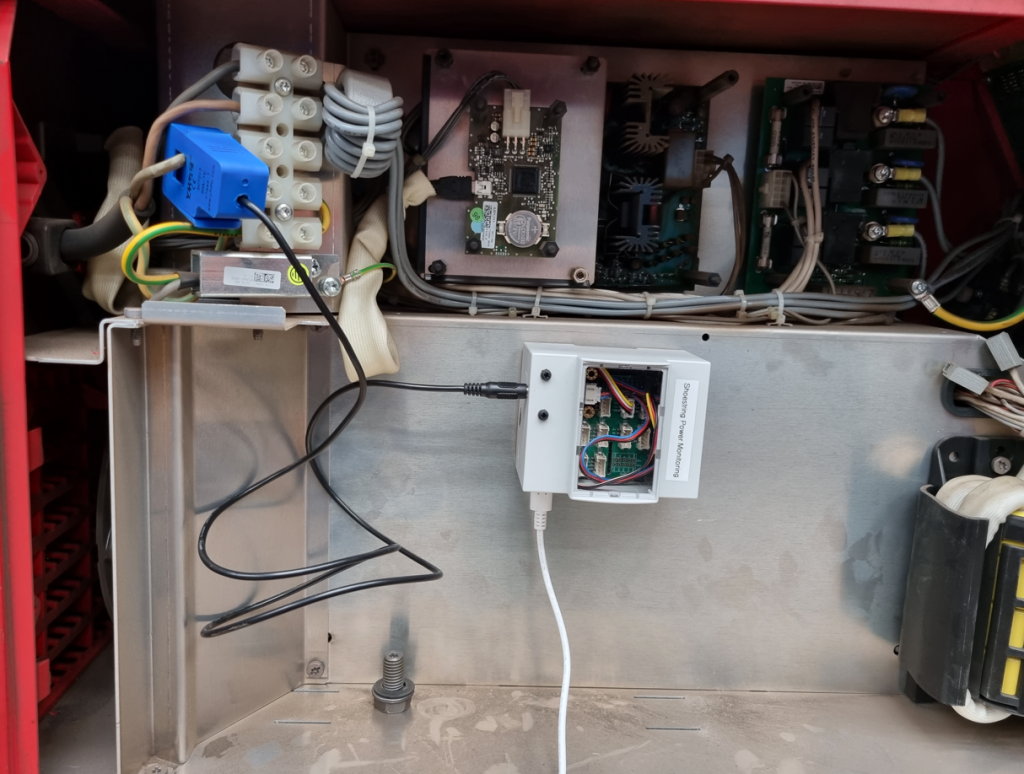

Use the power monitoring starter solution to visualise live current, apparent power and active power as well as historic power and energy consumption of your electrical equipment. Using a current sensor, which clips around the AC wire of the device you are monitoring, the data is displayed in an easy-to-read dashboard and can be stored and analysed over time.

Solves questions such as:

- Which equipment uses the most energy?

- Are machines using power out-of-hours (phantom load)?

- Which parts, products or operations have higher energy usage?

- Would new, more efficient machines save power and money?

Provides company benefits:

- Reduces energy usage and bills

- Contributes to sustainability goals

- Enables more accurate reporting on the carbon footprint of parts / products

Is simple to setup and use:

- Connect current clamp to the equipment’s power cable.

- Data from the clamp transmits to an easy-to-read live dashboard.

- The dashboard gives access to real-time and historic current, power and energy usage

Starter solution package

Special early adopter* rate of £400 (reduced from full cost of £800).

As an Early Adopter* you will get the starter solution package including:

- Bill of Materials – list of all the low-cost components you need to buy (costing you under £200).

- The starter solution’s software download.

- Full instructions on how to build and deploy the starter solution.

- Access to the online forum for support with problem solving.

- Places on the technical support programme led by the Shoestring engineer, with a cohort of 3-5 businesses, which includes:

- Specification and planning workshop (run online, c. 1.5 hours).

- Access to a series of online check-in sessions (each usually lasts 10-30mins).

- The Impact and review workshop (run online, c. 1.5 hours).

*Shoestring early adopters work in collaboration with Shoestring. They are among the first to trial the Shoestring starter solution package, receive direct support from the Shoestring technical team, and help Shoestring improve and develop the starter solution offering.

Tried and tested

Shoestring solutions have been deployed in over 70 companies, helping them to improve productivity, reduce waste and energy usage, and also to give their staff the digital skills and confidence they need to introduce more digitalisation throughout the business. Read or watch some of the industry case studies >

Job tracking solution | David Smith Ltd

Temperature monitoring | Kemdent Dental Products Ltd

Try another solution

Our range of Shoestring starter solutions is growing, currently you can also deploy:

- Job location tracking: to give visibility of where all jobs are at any time.

- Scrap monitoring: to help you reduce waste, produce more good parts, identify and address problems and improve stock planning accuracy.

- Downtime monitoring: to highlight machinery utilisation, which machines or operations have the most downtime, and the frequent reasons for downtime across production.

Or you can take out annual membership and access instructions and guides to all the solutions as well as join up to 3 training programmes.

Get started today

Buy your starter solution package now via our ecommerce site, and if you are a manufacturing company, take advantage of our half-price early adopter offer .

If you would like to talk to us, email contact@digitalshoestring.net or fill out our contact form.

Contact usComing soon

Drawing on the range of tried and tested solutions built and deployed in over 50 companies, Shoestring will release more starter solutions over the coming months, including scrap monitoring, machine downtime monitoring and temperature monitoring. Register your interest to be one of the first to know.