Shoestring completed demonstrators

Watch these videos for some examples of solutions development using low-cost components. These solutions have been developed in Shoestring’s laboratories to address some of the priority needs identified by SME manufacturers in the requirements gathering workshops. Some of the demonstrators are now being used in industrial pilots.

Find out how ‘DMW Factory’ addressed their business needs and introduced 3 digital solutions to their production line: Job tracking, Automated parts completeness checking & Equipment usage.

Part identification and tracking

This demo shows a low-cost digital solution for the identification and tracking of parts in a factory.

Augmented reality status viewer

Dr Greg Hawkridge explains an augmented reality tool for checking status of factory inventory.

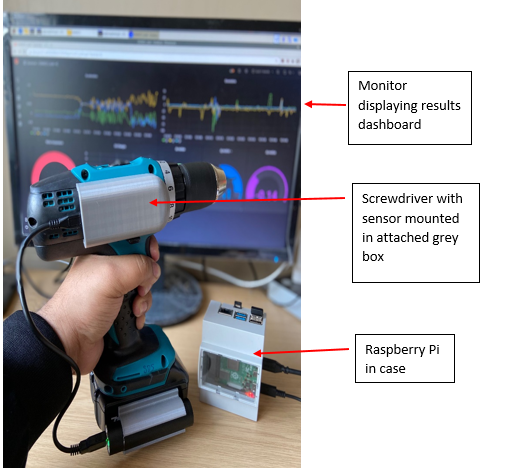

Machine monitoring

Dr Yedige Tlegenov demonstrates the use of low-cost sensors to monitor the status of factory machines and equipment.

Voice-assisted assembly

Dr Greg Hawkridge demonstrates the use of voice-assisted assembly using Alexa.

Touchscreen CNC router

This demo shows simple touchscreen technology for CNC routers.