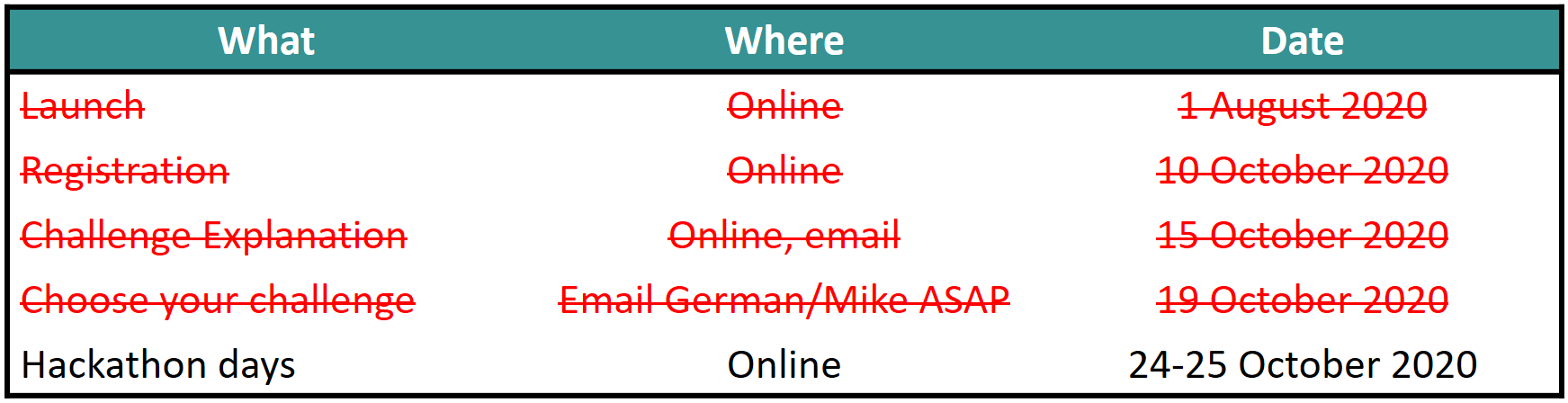

The Digital Manufacturing on a Shoestring project successfully ran its second sprint-like event on 24-25 October 2020. Unlike the first Shoestring hackathon run in 2019, this hackathon was held online due to the Covid-19 situation.

During the intensive competition over 100 students from the University of Cambridge and the University of Nottingham met online to create low-cost digital solutions for addressing real-world digital manufacturing problems that SMEs face.

Twenty-five teams participated across three different challenges: automated machine vision quality inspection, intelligent fault diagnosis assistance and virtual operational process planning. Each team managed to frame the problem, divide tasks, create solutions, integrate technologies, test and prepare outstanding presentations.

The 2020 Hackathon winners

An international panel of judges from Vos Voco, TQC, PTC and Paccurate assessed the solutions and declared ∑ of Parts the overall winner of the competition and winners of the automate vision quality inspection challenge. In the other two challenges, Error404 was the winner of intelligent fault diagnosis assistance, and The Bowden Cables the winners of the virtual operational process planning challenge.

It was a great online event where students not only built prototypes with cutting edge digital technologies, but more importantly, had fun while learning – congratulations to everyone!

The awards ceremony can be watched online here.

Challenges

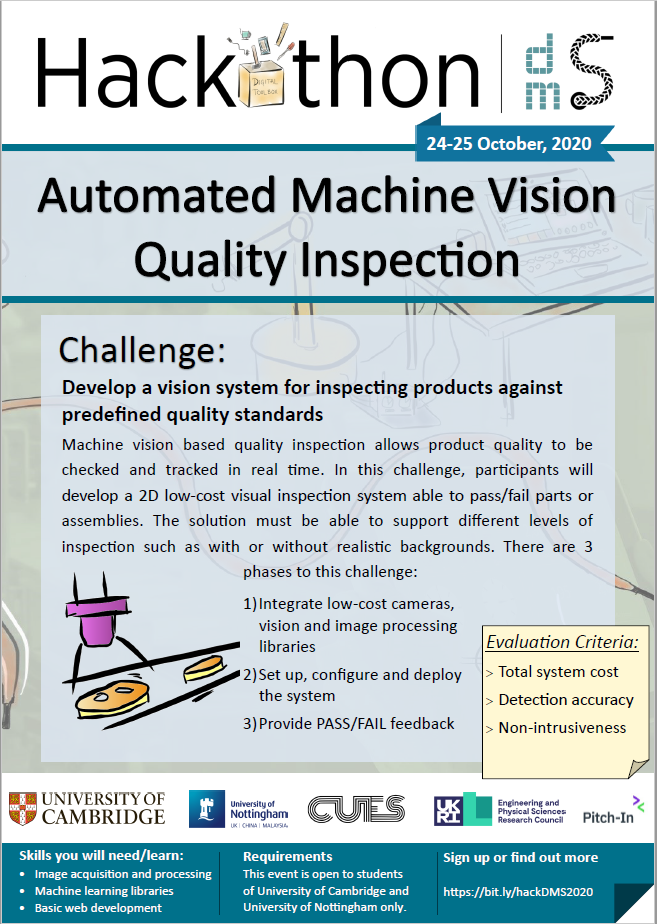

Challenge 1: Automated Machine Vision Quality Inspection

Machine vision based quality inspection allows  product quality to be checked and tracked in real time. In this challenge, participants will develop a 2D low-cost visual inspection system able to pass/fail parts or assemblies. The solution must be able to support different levels of inspection such as with or without realistic backgrounds.

product quality to be checked and tracked in real time. In this challenge, participants will develop a 2D low-cost visual inspection system able to pass/fail parts or assemblies. The solution must be able to support different levels of inspection such as with or without realistic backgrounds.

Challenge 2: Intelligent Fault Diagnosis  Assistance

Assistance

Manufacturing equipment can be very complicated, especially when it comes to fixing faults or errors. In this challenge, participants will develop a chatbot system that helps workers work out what is wrong and guides them through the process of fixing it.

Challenge 3: Virtual Operational Process Planning

Maximising operational efficiency within an SME is important for minimising delivery time while increasing profit margins. In this challenge, participants will develop an online system for optimising operational logistics and packing. The solution must be able to capture key operational processes of a multi-site company or a shopfloor.

important for minimising delivery time while increasing profit margins. In this challenge, participants will develop an online system for optimising operational logistics and packing. The solution must be able to capture key operational processes of a multi-site company or a shopfloor.

Furthe r information about each challenge can be found in the hackathon flyer – Shoestring hackathon flyer.

r information about each challenge can be found in the hackathon flyer – Shoestring hackathon flyer.

Download

Please download and read these documents which provide key information:

Judging criteria & awards

Judging will be done by an independent panel of judges from both academy and industry. All digital solution prototypes will be assessed in terms of low-cost development, technical aspects and presentation.

All submitted and presented challenge solutions compete for a prize pool of £400.

To enter

Sign up or find out more at https://www.instagram.com/p/CFJy3DJJQ4Y and https://www.facebook.com/events/321200025850711

Organisers

This hackathon is organised by the Distributed Information and Automation Laboratory at the Institute for Manufacturing, the Precision Manufacturing Centre at the Institute for Advanced Manufacturing and Cambridge University Engineering Society.

Where

Given the unprecedented COVID-19 situation, this event will be held online by the Institute for Manufacturing, University of Cambridge, and the Institute for Advanced Manufacturing, University of Nottingham.

Supported by

With thanks to the supporters of this event…