If your company needs a low risk, low-cost way to start digitalising, and would benefit from job tracking, power monitoring or temperature monitoring, try out one of Shoestring’s starter solutions with the SMDH project.

The first Shoestring starter solutions have just been released for companies to trial in the East of England, West Midlands, Scotland and Northern Ireland, as part of the research project, the Smart Manufacturing Data Hub project (SMDH).

Following over 25 industrial pilots, Shoestring has developed these three starter solutions to help address the top business needs of manufacturing companies. And more solutions will be released throughout the rest of the year.

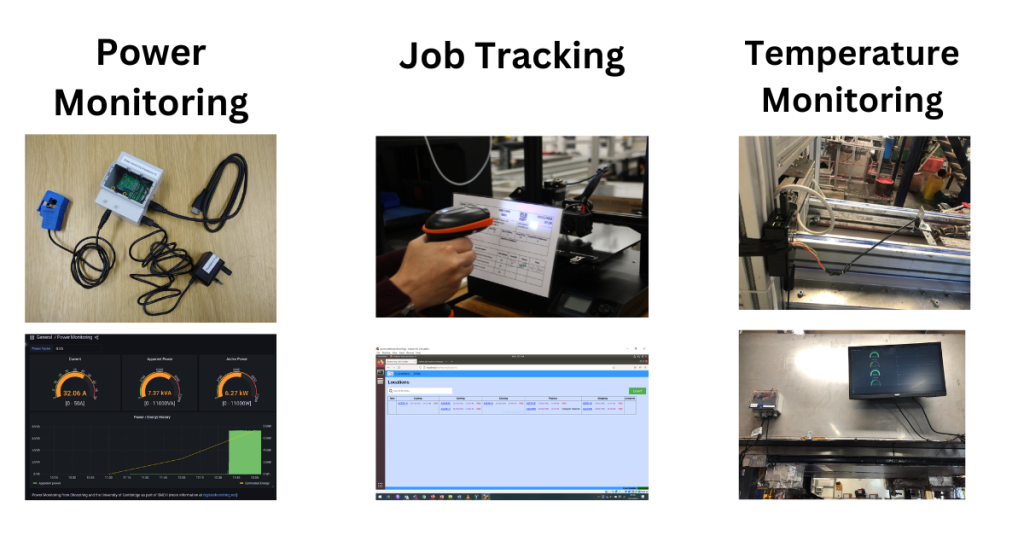

Power monitoring Help understand energy consumption by tracking actual equipment usage

Use this starter solution to visualise live current, apparent power and active power as well as historic power and energy consumption of your electrical equipment. Using a current sensor, which clips around the AC wire of the device you are monitoring, the data is displayed in an easy to read dashboard and can be stored and analysed over time.

Job tracking Improve productivity with real-time visibility of jobs on the shop floor

Using barcode scanners your operations team can help capture data about the real-time location of jobs in production, which will then be presented on a dashboard, so that all jobs in the production line can be found instantly. Read the industry case study >

Temperature monitoring Understand your processes better and see how temperature data could help you improve product quality

Using sensors, placed on equipment, or in an area, you can monitor ambient, equipment or process temperatures and set alerts to make sure you anticipate problems on the production line. The solution can also help you identify optimal temperatures for best quality production. Watch the 4 minute case study >

Starter solutions available via SMDH

In the first phase of the release we are offering companies that join the Smart Manufacturing Data Hub (SMDH) access to these starter solutions. SMDH supports small- and medium-sized manufacturers to become more competitive by harnessing the power of data. Digital tools and expert guidance are available to companies through the Hub, allowing them to explore and evaluate their processes, make operational savings, de-risk investments and make their factory smarter. Individual companies will be able to submit their manufacturing data – via a Manufacturing Data Exchange Platform (MDEP) which is currently in development – add to it over time and receive extracted intelligence in return. SMDH analysis is provided by expert data scientists, not normally accessible to an individual SME.

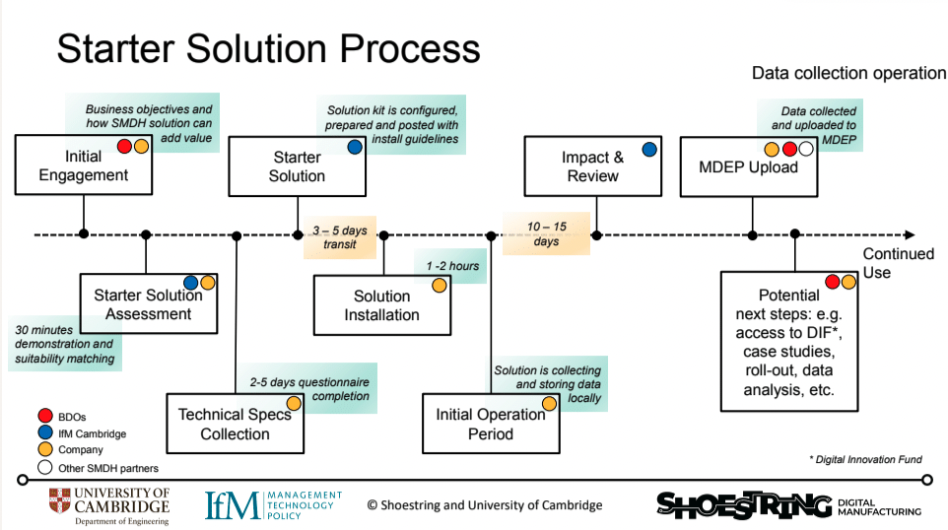

Starter solution process

The starter solution process should take a company from enquiry to an in-company starter solution trial within one month.

The timeline below shows how following an initial engagement with one of SMDH’s Business Development Officers (BDO) the Institute for Manufacturing (IfM) research team (at the University of Cambridge) will assess the starter solution required, and if appropriate will collect the technical specification from the company. Solution installation should only take the company up to 2 hours, after which the company will use the solution to collect data. After a period of time companies get in touch with the IfM team to help them assess the actual and potential impact of the solution. The SMDH team will then help the company upload the data to the secure MDEP platform and access expert advice from SMDH’s data analysis team.

For more information on how to join SMDH and access Shoestring’s starter solutions contact German Terrazas via email gt401@cam.ac.uk