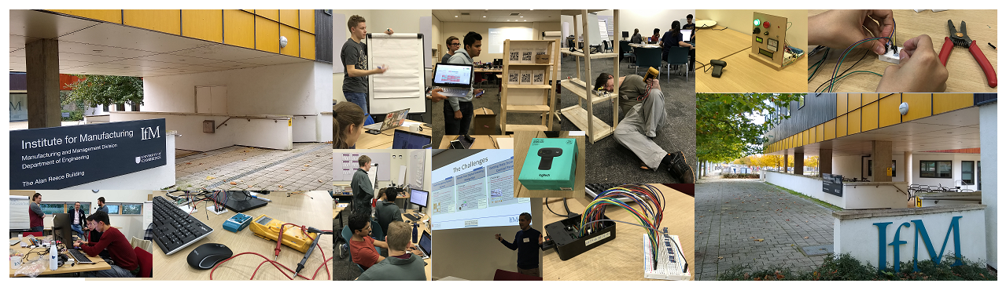

The latest Shoestring hackathon gave students a taste of what it is like to solve real-life manufacturing challenges and the chance to develop their team, project management and technical skills.

The Digital Manufacturing on a Shoestring project successfully ran its third sprint-like event on 12-13 February 2022. This high intensive competition attracted over 50 students, from the Universities of Cambridge, Nottingham and Sheffield, who registered to create low cost digital solutions to address real-world digital manufacturing problems that face small- and medium-sized companies (SMEs).

Nine teams participated across two different challenges: ‘Machine energy monitoring’ and ‘Analysis of product or customer demand’. For ‘Machine energy monitoring’ the challenge was to develop a bolt-on energy monitoring system for manufacturing equipment. The other challenge involved developing a system to understand the impact of promotional activity on the sales of SME products at retailers.

Each team picked one challenge and managed to frame the problem, create solutions, integrate cutting edge technologies, test and prepare outstanding presentations. A panel of judges from East Anglia University, PCML, AMRC and PrediTech assessed the solutions and declared The Fantastic Five the overall winner of the competition and winner of the ‘Machine energy monitoring’ challenge.

MXSOLUFINDERS were the winning team for the ‘Analysis of product or customer demand’ challenge with their shelf self-monitoring system. The team built a non-intrusive smart shelf using components that cost only £33.43 in total, comprising an Arduino Feather and electronic scale load cell sensor, alongside open source software InfluxDB, Python and Graphana. While Team Aglet received the Judges Innovation Award for their ‘Machine energy monitoring’ solution, built for £105.55 using a Raspberry Pi, low-cost sensors, a 3D printed case and open source software.

Feedback from the hackathon showed that the students had fun while learning, not only developing their technical skills but also enjoying working in multi-disciplinary teams and managing the project to deadline.

Karina, Alberto and Rey, from Team MXSOLUFINDERS, recommend that students of all levels should just try a hackathon and not worry if they think they don’t have enough knowledge. Rey said:

Two Engineering lecturers from FE Colleges in the UK observed the hackathon and spoke to the participants, both interested in how a modified version could help enthuse younger students. One commented:

If you are interested in finding out how you could run your own Shoestring hackathon for your students or staff contact us, email contact@digitalshoestring.net

Supported by

With thanks to the supporters of the February 2022 Shoestring hackathon: