As EPSRC funding concludes, Digital Manufacturing on a Shoestring enters the next stage.

This week, at the final meeting for the EPSRC-funded part of the Digital Manufacturing on a Shoestring project, partners and the research team celebrated the project’s extensive achievements to date and revealed the next stage as it transitions to a community programme.

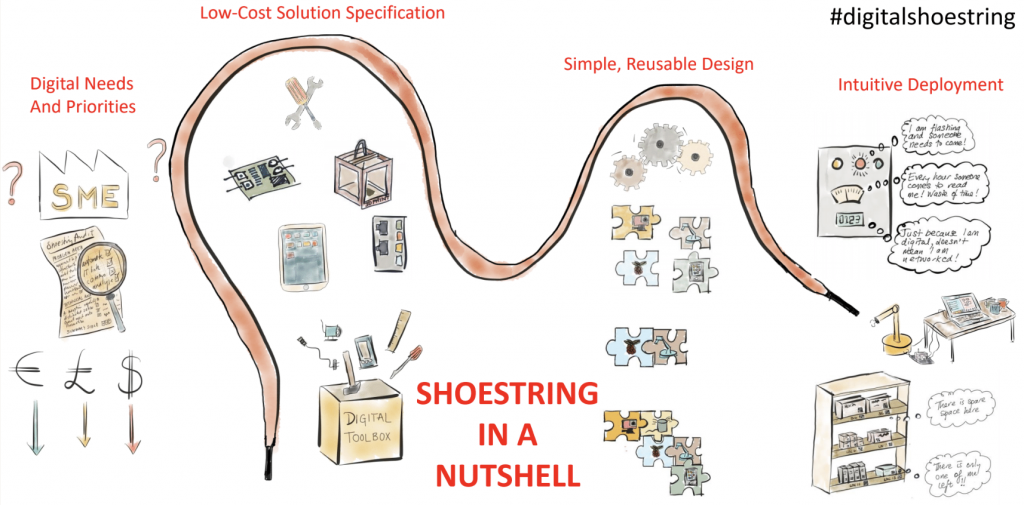

The Institute for Manufacturing (IfM) hosted partners and supporters of the Shoestring research project to mark the conclusion of the EPSRC-funded first stage of the project. Over the past three and a half years Shoestring demonstrated that there is a low-cost, low risk way to enable small- and medium-sized companies (SMEs) to start digitalising quickly and easily using affordable off-the-shelf technologies.

As the meeting drew to a close, one of Shoestring’s first partner’s, Andrew Cowey from Cowenco (formerly at Siemens), commented:

The early presentations summarised Shoestring’s key achievements – including the 25 requirements gathering workshops conducted with almost 400 companies, the compilation of a digital solution catalogue which spans 40 solution areas, the 25 specification workshops, a comprehensive design approach for low-cost digital solutions which led to 20 industry pilot deployments and the four hackathons run to date with over 200 students.

With support from other funding bodies and companies (CIH/CDBB, Gatsby Trust, Impact Accelerator Fund, Boeing, GS1 and Pitch-In) the project extended its impact with extra achievements including the creation of spin outs in construction, logistics and healthcare, plans for a regional roll out of Shoestring to SMEs and the overseas take up of Shoestring. Additionally, activities with education providers over the past 6 months will help establish an education and training pilot to facilitate students, apprentices and lecturers to help deploy digital solutions in industry.

The second half of the meeting focussed on future developments. A new business unit has been established, which will be run out of the knowledge transfer consultancy within the IfM, IfM Engage, while the unit establishes a financially sustainable not-for-profit organisation which will provide SMEs with a low-cost, low-risk step-by-step approach to deliver tangible company improvements using digital technologies.

Professor Duncan McFarlane, founder and lead for the Shoestring project, said:

If you missed the event, and would like to hear more details, please get in touch.

We would like to thank all the partners for their continued support for the Shoestring project.

If you would like to find out how your organisation could benefit from Shoestring, email us: contact@digitalshoestring.net