Two collaborative research projects, Connected Factories and Elastic Manufacturing, are developing a multi-site demonstrator using Shoestring solutions

The Made Smarter Connected Factories Centre (MSCF) and Elastic Manufacturing System (EMS) projects are two ongoing research projects funded by EPSRC and InnovateUK at the Institute for Manufacturing (IfM). Connected Factories (MSCF) is a collaboration with the Universities of Nottingham and Sheffield. It aims to support advanced production systems that respond to changing supply and demand by adapting, repurposing, relocating, and reusing available production capabilities. Elastic Manufacturing (EMS), a project with the University of Nottingham and Imperial College London, investigates the ability of manufacturing systems to scale output up or down quickly to meet changes in customer demand while remaining profitable.

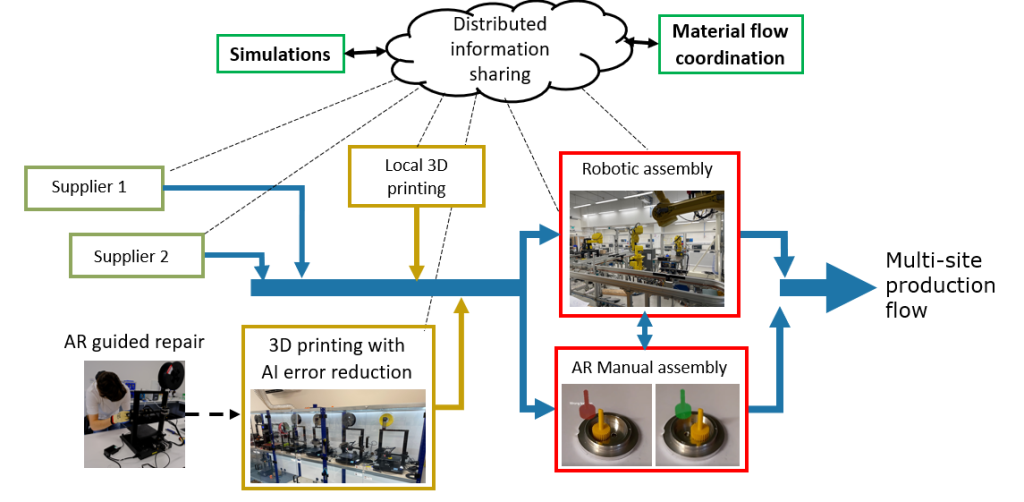

As part of both projects, a multi-site demonstrator is being developed in the IfM, which aims to replicate the way in which many SME companies operate and interact. Different components are produced in sites acting as individual factories within the IfM. Production is coordinated across multiple locations. Previous research in manufacturing has often focused on a single production location not multiple; the new demonstrator will enable us to investigate solutions to support production across multiple locations. The Shoestring solutions help facilitate quick upgrades to existing production equipment to create smart factories and capabilities. Examples of solutions combined in the demonstrator include:

- Job Tracking – Barcode scanners are used to track orders through each factory; information on the progress is then shared between sites to help improve delivery estimates.

- Energy monitoring – The Shoestring energy monitoring starter solution provides information on the energy use of equipment such as 3D printers and assembly robots.

- Fault tracking – Faults in incoming parts and final products are recorded by operators using an app that can be loaded on a phone or tablet to ensure issues such as poor-quality materials are recorded.

Now that these solutions are in place, the next stage will focus on integrating simulations, investigating what information should be shared between sites to support production and how it should be shared.

The diagram above shows the Institute for Manufacturing’s different facilities and locations involved in the demonstrator and the production flow.

Does your production occur across multiple sites?

The Connected Factories (MSCF) and Elastic Manufacturing (EMS) research team would like to engage with companies operating across two or more sites to understand the challenges of operating in this way. For example:

- Challenges with communicating information between sites? Is key information shared effectively between the sites?

- Challenges with Sharing effectively between the sites?

- Issues with tracking goods as they move between sites.

- Delay and mismatches in synchronising operation?

Of particular interest is whether the software of digital technologies supports or impedes these operations. If you would like to explore these challenges further, please contact Dr Sam Brooks at sjb351@cam.ac.uk, who would be keen to hear from you.

If you’d like to find out more about the Connected Factory and Elastic Manufacturing projects, please contact Dr Sam Brooks at sjb351@cam.ac.uk.