Shoestring is enabling small and medium sized companies to accelerate their digital journey via the Made Smarter Smart Manufacturing Data Hub.

Over the past few months three Shoestring standard solutions, Power monitoring, Temperature monitoring and Job tracking, have been available to companies in specific regions as part of the Smart Manufacturing Data Hub project (SMDH). Access to the hub is now nationwide, so companies in other regions such as Wales and the West Midlands can now also sign up to SMDH and if they need a low-cost way to start collecting data, use one of Shoestring’s standard solutions.

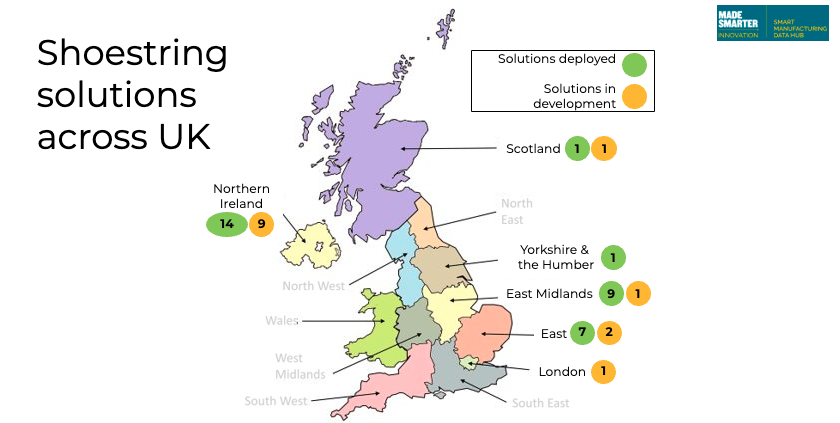

The Smart Manufacturing Data Hub is a research programme set up to support small- and medium-sized companies to become more competitive by harnessing the power of data. So far Shoestring has engaged with nearly 50 businesses across the UK of which over 30 have already installed one of Shoestring’s low cost sensor-based solutions. Companies are using these solutions to collect and upload the data on SMDH’s online platform, so that they can access the Hub’s data scientists and learn first hand the benefits of data analytics.

Currently there are three solutions available, Power monitoring, Temperature monitoring and Job tracking.

For more information on the solutions, and how you can access them via the Smart Manufacturing Data Hub, read our previous news story.

To find out how a bespoke footwear company deployed and benefits from the Job tracking solution, read the Buchanan Orthotics case study. Or watch the video located at the top of the Industry Case Study page which illustrates how a dental manufacturer used the temperature monitoring solution to improve the quality of their wax products.

If you’d like to find out how you can install a Shoestring solution and join up with the Smart Manufacturing Data Hub please contact Dr German Terrazas gt401@cam.ac.uk.