Digital Manufacturing on a Shoestring is setting up a factory production line at Digital Manufacturing Week (DMW) in Liverpool, 10 & 11 November.

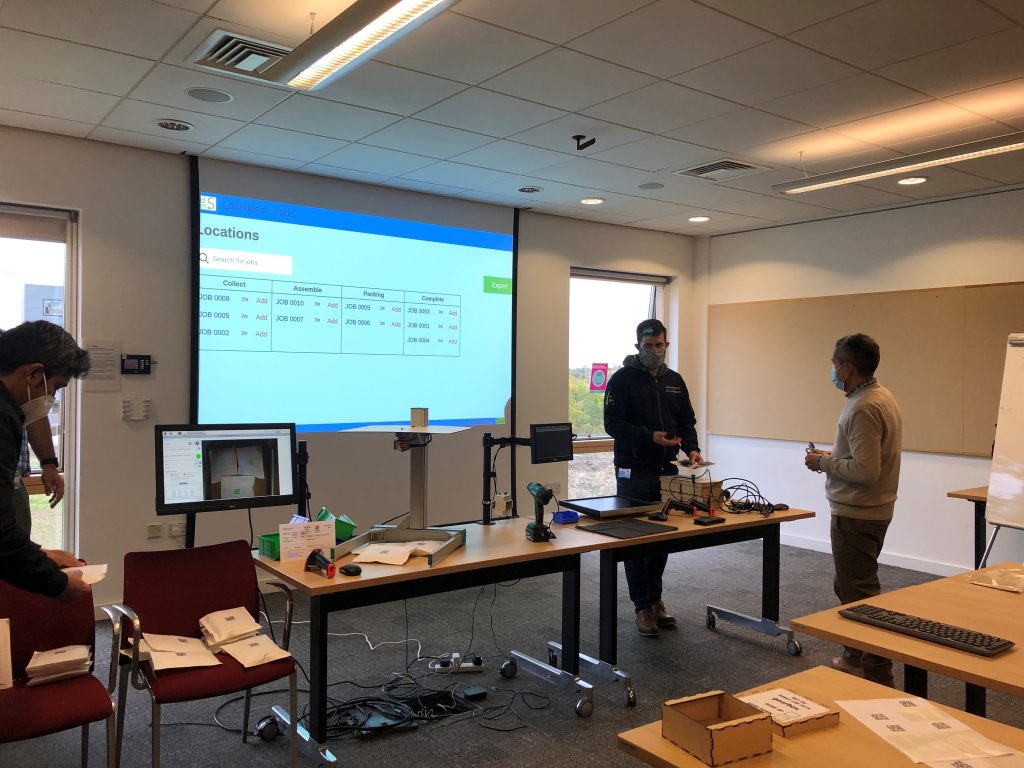

Following the Shoestring approach, the ‘DMW Factory’ has implemented three of Shoestring’s low-cost digital solutions to help improve efficiencies on a gearbox production line. These solutions can be viewed in action for the first time in a mock-up production line featured on part of the Institute of Manufacturing’s exhibition stand at Smart Factory Expo this year.

Job tracking was implemented first by the ‘DMW Factory’, to give real-time visibility on the status of all the jobs in production – indicating at which stage each job is. Two more solutions were then added. Automated parts completeness checking was added to workstation 1 to apply an automated way to check that all the right parts are collated before being sent to be assembled. Then, at workstation 2, an equipment monitoring solution was added to monitor the use of a screwdriver used to assemble the products.

You can read the full details on how this live factory demonstrator was put together here.

If you are visiting Digital Manufacturing Week in Liverpool, come and see the digital solutions in action on the Institute for Manufacturing’s exhibition stand, J50, in the Smart Factory Expo.

Watch a run through of the ‘DMW Factory’ digital solutions that will be featured on the IfM stand at Smart Factory Expo.

If you are interested in finding out how your company or organisation can get involved in the Shoestring programme, or would like to know more, we would love to hear from you!

Please email us at: contact@digitalshoestring.net