A temperature monitoring pilot at dental manufacturer, Kemdent, gave the staff confidence to digitalise more processes across the company

After deliberating about how to incorporate digitalisation into their processes, dental manufacturer Kemdent approached the Shoestring team to see if they could help. Within several months they had implemented a digital solution onto one of their production lines, improving the efficiency and quality of their operations.

Thanks to the straightforward Shoestring approach, Kemdent were able to identify their key business challenges and decide which one would be easiest to address with a digital solution.

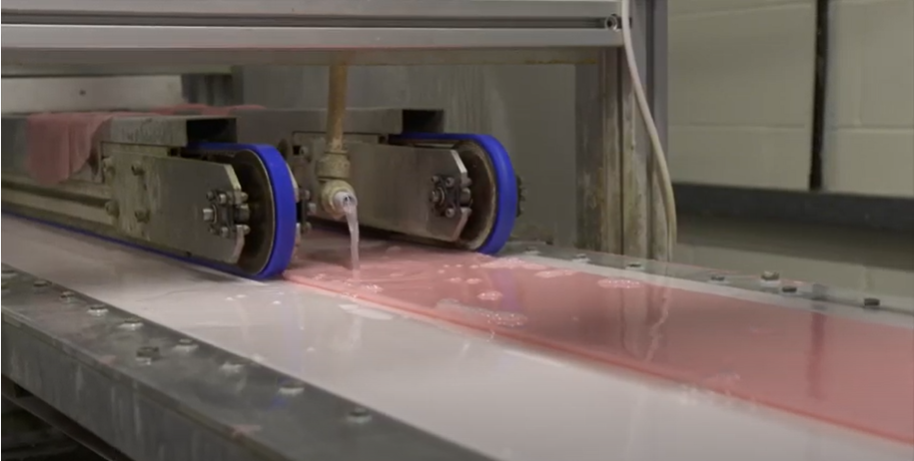

In this case, they decided to try to pre-empt problems caused by temperature changes during the wax forming process. By installing a low-cost temperature sensing system across one production line, they were able to check that wax cooled at the right rate to avoid hardening too fast and causing defects in the final product.

The Production Supervisor led the implementation, with remote support from the Shoestring team, learning how to set up a Raspberry Pi – connected to an infrared sensor – so that the temperature could be collected and read in real-time as well as analysed over time. Craig Mayoh, Operations Director at Kemdent, explains:

Since the first trial of the solution, Kemdent has rolled out the temperature sensor across the shopfloor, adding more sensors and microcomputers, so that they can monitor several production lines simultaneously.

And they are now looking at adding a second Shoestring solution to build on their digital capabilities and further improve efficiencies. Craig Mayoh recommends Shoestring to any manufacturer keen to start digitalising but unsure of how to start:

Find out how a construction manufacturer saw immediate benefit from Shoestring with their Job tracking solution >>

For more details on Shoestring’s industry pilots see our case study page >>

If you are interested in finding out how your company or organisation can get involved in the Shoestring programme, or would like to know more, we would love to hear from you!

Please email us at: contact@digitalshoestring.net