PLEASE CLICK HERE to read the news story on the winners and outcome from the hackathon

**Please NOTE: This is a HYBRID event, whilst it is online, students may participate in person at the IfM / IfAM**

After the successful Shoestring hackathons run in 2019, and online in October 2020 the members of the Shoestring project are organising the third event of this kind – to be held 12-13 February 2022 – targeted at students of the University of Cambridge and the University of Nottingham. This hybrid hackathon – which will be conducted both online and at the IfM and IfAM for those students who would like to attend in person – invites students to address creatively some of the real-world digital problems manufacturing SMEs face by using low-cost off-the-shelf and open-source technologies.

The hackathon aims at the construction of digital solution prototypes in areas such as monitoring, cost modelling and product/customer demand analysis, requiring students to work with off-the-shelf and open source technologies as well as pieces of hardware, like cameras or microcontrollers.

Subject to the unprecedented COVID-19 situation this event will be held online on 12-13 February 2022, 0900:-18:00 each day. However, students have the option of working at home or in The Institute for Manufacturing (IfM) in Cambridge or the Institute for Advanced Manufacturing (IfAM) in Nottingham.

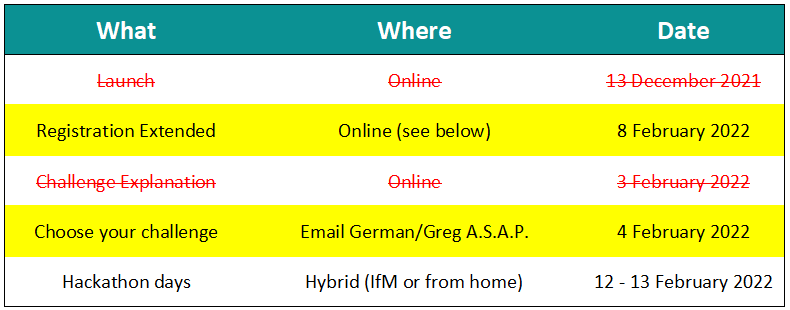

Important Dates

PLEASE NOTE: This is an online (hybrid) event for students of the University of Cambridge and the University of Nottingham.

Challenges

The three hackathon challenges are:

Challenge 1: Machine Energy Monitoring

Challenge 2: Cost Modelling of Disruptions and Changes

Challenge 3: Analysis of Product or Customer Demand

CHALLENGE 1: Develop a bolt-on energy monitoring system for manufacturing equipment

Many manufacturers have little insight into how much energy their equipment uses. Better insight into energy usage can facilitate decision making and motivate operational changes that lead to reduced energy usage and therefore costs. In this challenge you will develop a simple bolt-on system that can be attached to a piece of equipment to log its energy usage. There are 3 phases to this challenge:

- integrate low-cost sensors to collect data

- Set up, configure and deploy the system

- provide a visual dashboard

Evaluation criteria: Total system cost / System flexibility / Non-intrusiveness

CHALLENGE 2: Develop a simple but efficient costing system that captures project disruptions and changes

Capturing changes and disruptions in manufacturing processes can help organisations track and understand the final cost to produce a product. In this challenge, participants will develop a cost system that considers impact of changes, e.g. from BOM (Bill of Materials), labour or suppliers, in manufacturing process plans. There are 3 phases to this challenge:

- Interface with a system that stores changes in manufacturing processes

- Develop a cost model that calculates the cost of changes

- Visualise the results

Evaluation criteria: Ease of interaction / System accuracy / Information display

CHALLENGE 3: Develop a system to understand the impact of promotional activity on the sales of SME products at retailers

Small food producers who sell their products via large supermarkets are encouraged by those organisations to run promotions or discounts on their products. The impact of these promotions is rarely assessed or interpreted. Further, there is no meaningful feedback on the availability of product during a promotional event, so SMEs do not know if their rate of supply is matching demand or if their products are on shelves in stores for customers. There are 3 phases to this challenge:

- Develop a system that collects actual data on the movement of goods within the supermarket

- Provide feedback on the impact of a promotional event on sales performance

- Generate real time alerts when there are no goods on the shelf in a supermarket

Evaluation criteria: Total system cost / Reliability / Non-intrusiveness

Download

Please download and read these documents which provide key information:

*updated 02/02/2022 for hybrid event

Judging criteria & awards

Judging will be done by an independent panel of judges from both academy and industry. All digital solution prototypes will be assessed in terms of low-cost development, technical aspects and presentation.

All submitted and presented challenge solutions compete for a prize pool of £400.

To enter

Registration is now open:

- University of Cambridge students, click here for the Cambridge form.

- University of Nottingham students, click here for the Nottingham form.

Students at the Universities of Cambridge and Nottingham can enter. You may register as a team of 4-6, or individually or as a smaller group, in which case we will arrange teams for you.

Organisers

This hackathon is organised by the Distributed Information and Automation Laboratory at the Institute for Manufacturing, the Precision Manufacturing Centre at the Institute for Advanced Manufacturing and Cambridge University Engineering Society.

Where

Given the unprecedented COVID-19 situation, this event will be held online, organised remotely by the Institute for Manufacturing (IfM), University of Cambridge, and the Institute for Advanced Manufacturing (IfAM), University of Nottingham. However facilities will be available for students to work at either the IfM in Cambridge or IfAM in Nottingham.

Contact us

German Terrazas

Greg Hawkridge

Giovanna Martinez

gt401@cam.ac.uk

gth24@cam.ac.uk

giovanna.martinezarellano@nottingham.ac.uk

Supported by

With thanks to the supporters of this event…